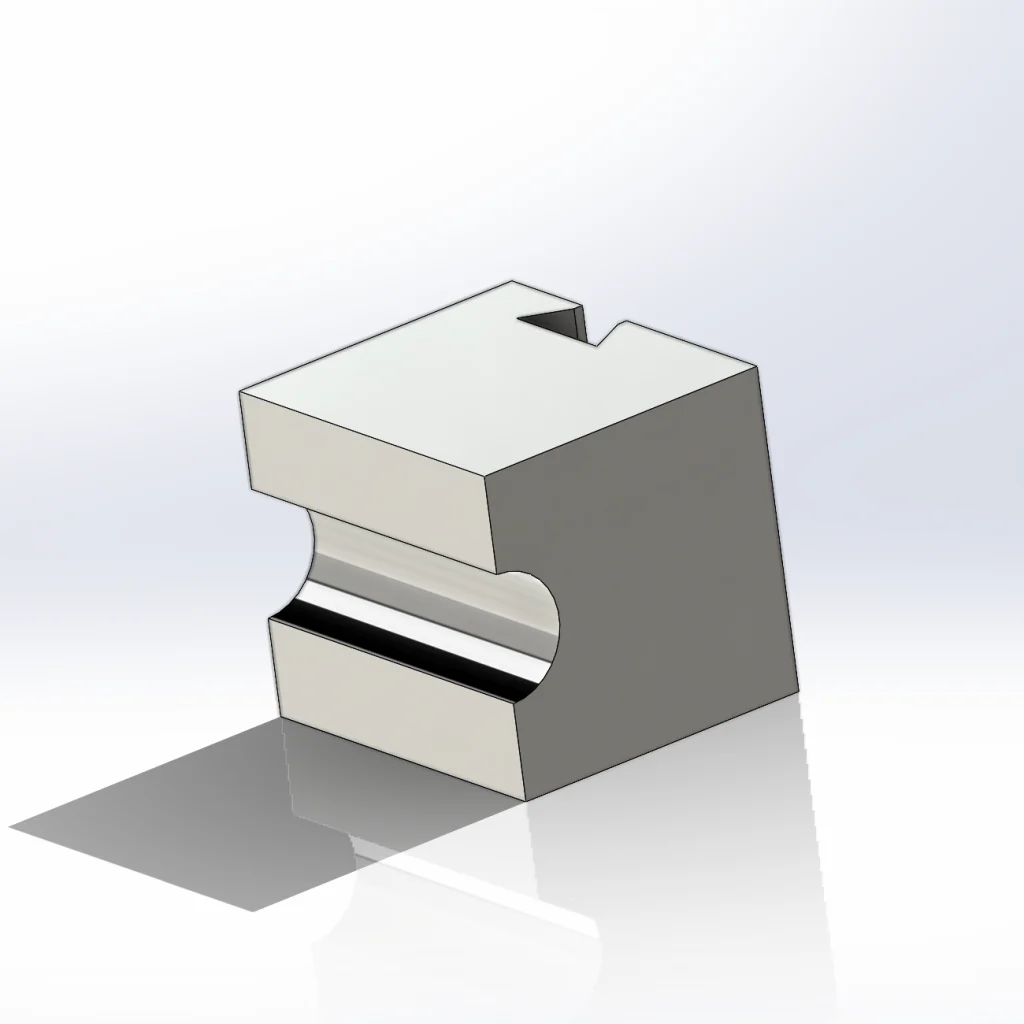

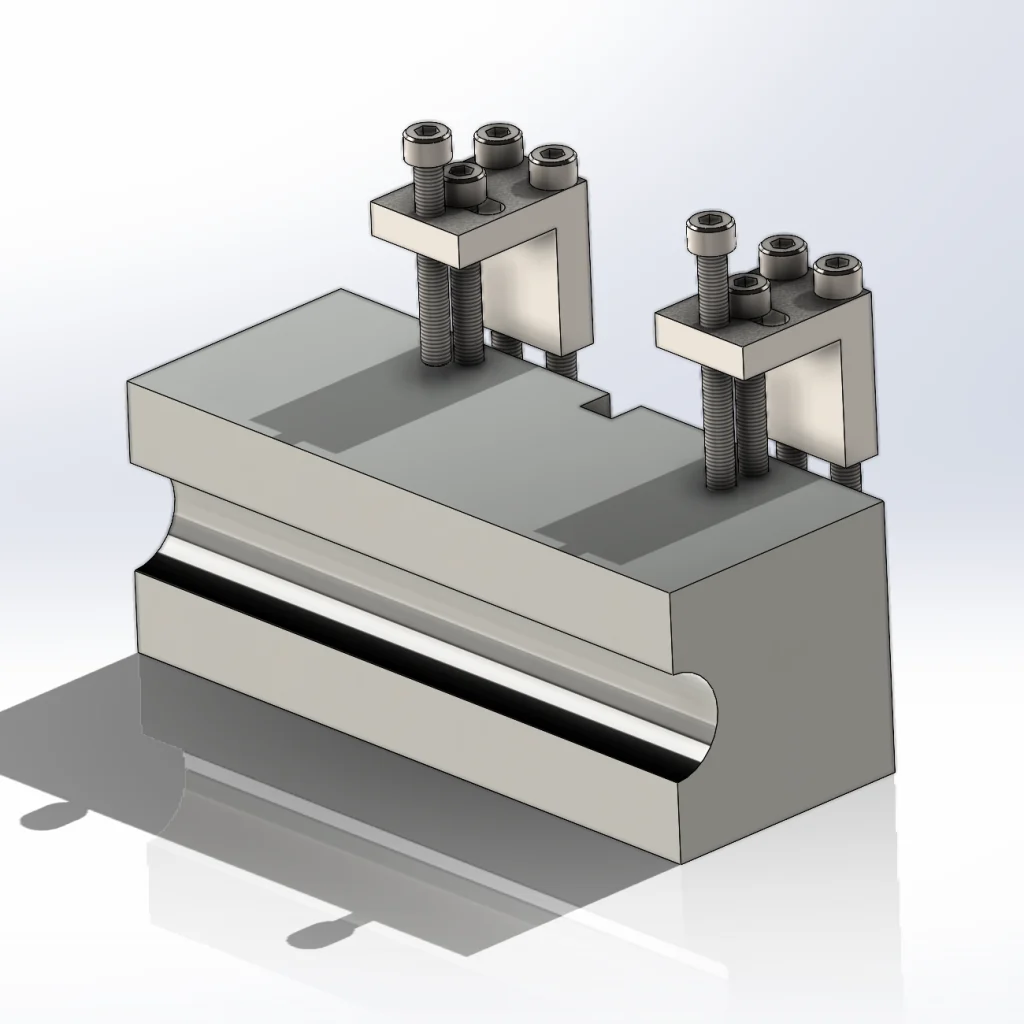

Pipe Bending Tools

At SNE MACHINES, we go beyond just technology. We take pride in delivering an exceptional manufacturing experience through our cutting-edge technologies and comprehensive tool support. Our devoted team is committed to providing you with access to the right tools and resources, offering expert assistance and guidance at every step of the process. Whether you need maintenance, troubleshooting, or customization, our tool support services are meticulously designed to optimize the efficiency and performance of your operations. Partner with us for not only state-of-the-art equipment but also a complete support system that guarantees your success.